The Astec Positive Aspect

- Initial American manufactured full lumber pellet plant producer

- One supply for full set up plus 24/7 assistance and service

- Revolutionary, industry-changing total plant design and features

- Any lumber species, with no thermal oxidizer needed

- Emissions below Title 5 limit to 850, 000 tons per year

- Fast construction and startup with guaranteed manufacturing prices

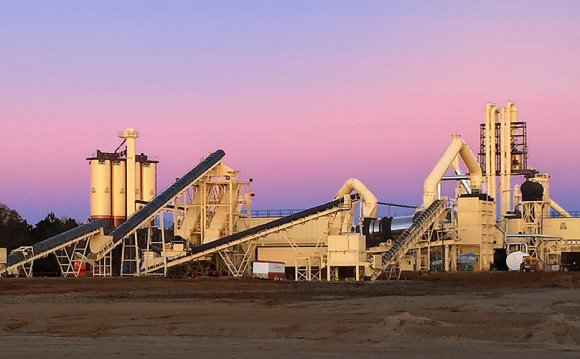

Astec's ground-breaking, advanced wood pellet plant features many industry-firsts and is poised to alter the wood pellet manufacturing industry. Astec, Inc. is an associate of Astec Industries, Inc. group of businesses, a billion dollar per year company based in Chattanooga, TN, USA. Astec is focused on providing the finest gear on the planet to infrastructure, energy and forest organizations.

The standard design with replicated parallel lines results in there being very few points along the way where any equipment failure can close the whole plant down. Generally in most other plants, any dryer outage means a total plant shutdown. In a 60 TPH Astec plant, a dryer outage means the plant consistently run at 40 TPH. Indeed, you can find hardly any reasons why the plant would previously be completely shut down. Even significant maintenance cycles might done line-by-line whilst plant consistently are powered by one other lines. Redundant design reduces peace and quiet.

- Each plant consists of 20 TPH rated "lines".

- Each line is in result a plant component.

- For plants larger than 20 TPH, additional lines are given. As an example, a 60 TPH plant includes [3] 20 TPH outlines.

Hot Oil Tube Dryer

Modular Pellet Plant Layout

Innovative Modular Design

ASTEC pellet plants tend to be fairly quick and easy to setup and start up considering ASTEC's modular design idea. Most major plant elements tend to be preassembled in our shops and sent to your site prepared carry from the vehicle and set into running position on an asphalt or concrete pad.

Verified Elements

The Astec pellet plant's components, almost all of which are built by Astec within manufacturing services situated in Chattanooga along with other U.S. locations, consist mainly of old gear that is in effective service and perfected for a long time under severe conditions of service around the world.

These proven fabrication designs have-been upgraded with all the latest technology to present the perfect timber pellet plant equipment these days.

Making use of proven gear, with several possible programs, provides Astec timber pellet plant proprietors, investors, and loan providers with a high level of item investment security.

Major components feature: real time bottom cold feed containers, a pre-dryer, 40M BTU convectec heater, 60M BTU burner, bio-mass pipe dryer, waste screw, 4, 000 gallon hot oil growth container, timber gasoline skid, screw conveyors, distributor screws, lumber fines conveying followers, pellet conveying fans, 50, 000 ACFM scavenge baghouse, future conditioner, pellet cooler, pellet collecting conveyor, dirt blower, bucket elevator, 5, 000 cubic legs loadout silos.

Major components feature: real time bottom cold feed containers, a pre-dryer, 40M BTU convectec heater, 60M BTU burner, bio-mass pipe dryer, waste screw, 4, 000 gallon hot oil growth container, timber gasoline skid, screw conveyors, distributor screws, lumber fines conveying followers, pellet conveying fans, 50, 000 ACFM scavenge baghouse, future conditioner, pellet cooler, pellet collecting conveyor, dirt blower, bucket elevator, 5, 000 cubic legs loadout silos.

Quick Startup

The Astec suspension system wood dust burners enable quick plant startups and shutdowns. Unlike old-fashioned burner methods that typically take all time or even more to "get up to date", Astec plant startups can get from dead cold to creating pellets within as little as 2-3 hours.

The Astec burner system is a multi-fuel burner which may be fueled by wood dust simultaneously with gas, oil, or liquefied petroleum fuel (LPG).

Better Drying and Emissions

The Astec pellet plant's exceptional drying and emissions controls technologies enhance safety, performance and produce less emissions.

We do not use traditional air-swept rotary dryers with inherent direct hot gasoline contact with very flammable wood dirt and chips. Most of the off-gases from the drying out procedure tend to be conveyed to the burning chamber of this hot oil heater in which any volatile natural compounds (VOCs) and fugitive wood dirt are eaten, perhaps not introduced. This means even really huge Astec pellet plants might run without RTOs.

Superior Protection

We utilize rotary hot oil pipe dryers. Drying by this process keeps the drying out potato chips in an almost oxygen-free environment. Almost no oxygen means hardly any chance of fire or explosion.

Settings Solutions and Training

Astec, Inc. controls solutions were created by a group of in-house settings designers and simulated inside our settings lab to integrate along with your facility and process.The Astec lumber pellet plant includes Astec TCII controls which are made to provide optimum real time control over all operations. Astec also provides consumers with settings training on-site, personally and also by phone from plant set up and throughout ownership.

Engineering

Astec engineers know their particular things. They use SolidWorks 3D design software to help you build a plant that fits your needs today as well as in tomorrow. Astec engineers have considerable field-experience and appearance toward planning plant websites. Astec offers complete engineering services including foundation, structural and layout solutions and help. An on-staff ecological Compliance management provides expertise to make the permitting procedure as simple as possible.

Components

The Astec parts department has a great trustworthiness of providing quick, expert customer care in enabling the parts you need when you really need all of them, because quickly and effectively as you can.

Provider

The Astec solution staff can be obtained for telephone calls and able to dispatch personnel to keep your plant flowing. A fully staffed, committed service department suggests somebody can be obtained to provide help irrespective of the time or day.

rtve researchgate astro.wisc.edu engawa.kakaku.com search.auone.jp id.telstra.com.au sitereport.netcraft.com wikimapia.org nutritiondata.self.com kaskus.co.id digitalcollections.clemson.edu superherohype.com tools.folha.com.br talgov.com minecraft.curseforge.com curseforge.com foro.infojardin.com camfrog.com popcouncil.org drinksmixer.com